POS System Inventory Management: 5 Practical Tips to Help Retailers Avoid Stockouts

In Hong Kong’s highly competitive and fast-paced retail market, running out of stock not only directly affects sales but can also drive customers to other brands and even undermine their trust in your store. How can retailers avoid the predicament of “hot-selling items are out of stock, while slow-moving items pile up”? The answer lies in smarter inventory management. Modern POS systems are exactly the right tool for retailers, automating tedious inventory monitoring and providing real-time data to support more accurate decision-making.

Today, Posify shares 5 practical tips to help you manage inventory with a POS system and keep your stock levels sufficient.

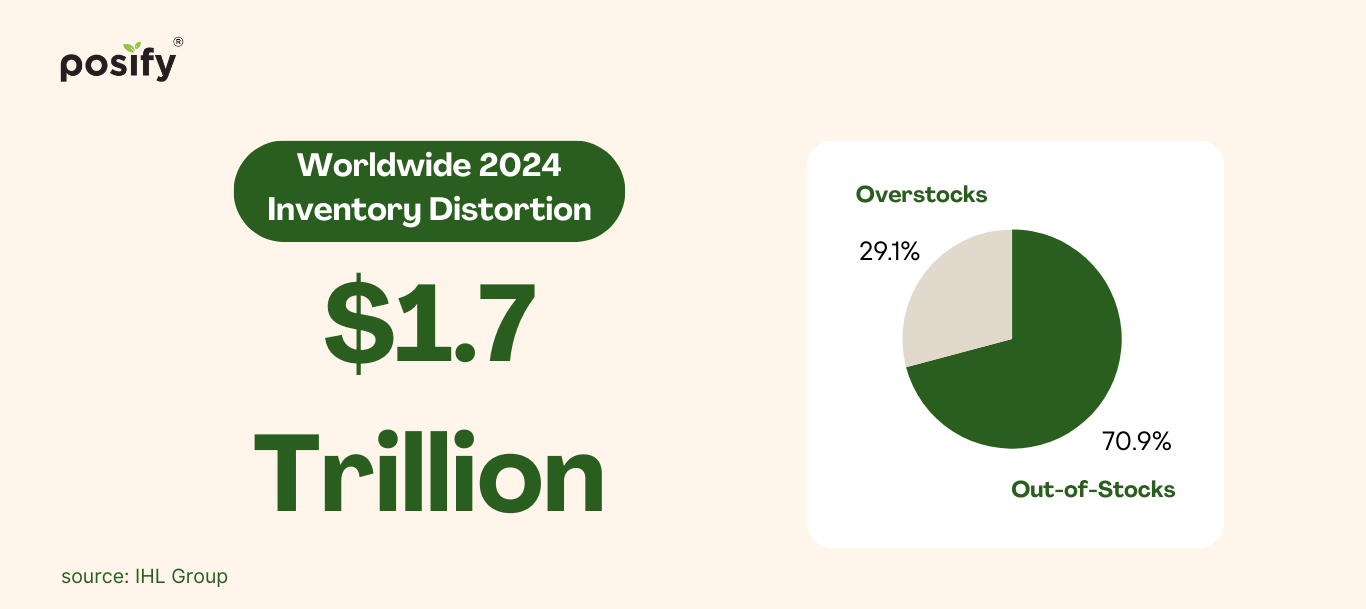

Key Insights: Inventory Mismatch Causes Major Losses in Retail

Global inventory distortion is a serious problem, continuously troubling retailers worldwide and causing significant financial losses and operational challenges. According to data from global research and consulting firm IHL Group, by 2024, the total cost caused by “inventory mismatches” is expected to reach USD 1.7 trillion. Although this represents a slight improvement of 3.7% compared to the previous year, the problem remains severe. Losses caused by out-of-stocks are estimated at USD 1.2 trillion, while the cost of overstocks amounts to USD 554 billion. Faced with such staggering figures, businesses that fail to make adjustments can only watch losses continue to grow.

3 Main Types of Retail Inventory

In Hong Kong’s retail sector, inventory management directly affects cash flow, operational efficiency, and customer experience. Generally, inventory can be categorised into three main types, each with its characteristics and management focus:

1. Cycle Stock

Cycle stock is the inventory that naturally exists in daily retail operations, supporting normal sales and replenishment cycles. For example, after placing an order with a supplier, it may take 3 to 4 weeks for goods to arrive in Hong Kong, creating “in-transit stock” during that period. Retailers also need to maintain a certain level of stock in-store or in the backroom to ensure shelves are not empty.

Given Hong Kong’s limited retail storage space, the key challenge in cycle stock management is balancing “well-stocked displays” with “minimising inventory buildup.”

2. Safety Stock

Safety stock serves as a buffer against demand and supply uncertainties. For example, demand may spike for refreshing beverages in the hot summer or festive items such as gifts and cards during Christmas. On the supply side, there are also many variables, especially since Hong Kong heavily relies on imports, where shipping delays or customs issues may cause stock shortages. The purpose of safety stock is to maintain a certain level of customer service (e.g., product availability or on-time delivery rate).

-

When demand surges unexpectedly, safety stock prevents stockouts.

-

When supply is delayed or disrupted, safety stock supports a certain level of fulfilment capability.

Because cycles are full of unpredictable factors, safety stock often runs parallel with cycle stock and is an unavoidable management element.

3. Excess Stock

Excess stock refers to inventory beyond reasonable demand, often regarded as “unplanned” or “inefficient” stock. Common causes include:

-

Inaccurate demand forecasting: Actual sales fall far below expectations.

-

Customer order cancellations: Pre-stocked inventory cannot be sold.

-

Minimum order quantity (MOQ) requirements: Purchases exceeding demand due to supplier or production unit requirements.

This type of inventory often ties up capital, increases storage costs, and, if not cleared over time, may lead to write-offs and asset impairment.

5 Practical POS System Tips to Help Retailers Avoid Stockouts

For retailers, inventory management is both an art and a science. Excess inventory increases storage costs and financial pressure, while insufficient stock may lead to stockouts, affecting customer experience and sales performance. Achieving inventory balance is not easy, but modern cloud POS systems provide inventory management functions to help retailers improve operational efficiency.

Here are 5 practical tips to help you avoid stockouts and boost operational efficiency.

1. Real-Time Product Inventory Tracking

In Hong Kong’s fast-moving retail market, products circulate rapidly, and traditional manual recording can easily be delayed, leading to stockouts or inaccurate inventory. Posify POS system provides real-time inventory data and supports batch number and serial number tracking, which is particularly important for products such as electronics and health supplements requiring strict management.

-

Batch number tracking: Retailers can clearly track the production date and expiry of each batch, avoiding expired or slow-moving stock occupying warehouse space.

-

Serial number tracking: Retailers can precisely monitor the movement and sales of each item, greatly assisting in after-sales service and maintenance management.

2. Setting Safety Stock Levels

In inventory management, the “safety stock level” is a crucial concept. It acts as a warning line; when stock falls to this level, the POS system immediately alerts you to replenish. For example, if you run a fashion store and set a popular pair of jeans’ safety stock at 20 units, the system will notify you when inventory reaches this level, allowing timely action. This ensures retailers still have stock during sudden demand spikes, preventing missed sales opportunities.

3. Automatic Replenishment Function

Modern POS systems usually have a built-in automatic replenishment function that generates purchase suggestions based on sales trends and inventory status. This is especially important for Hong Kong retailers, where market demand changes quickly, and manual tracking can lag behind. Posify supports a B2B mode, allowing automatic creation of Purchase Orders (PO) based on inventory levels and sending them to suppliers. This ensures accurate delivery timing, reduces human error, and guarantees popular products are stocked on time.

Contact our professional consultants on WhatsApp to learn more about the POS system!

4. Analyse Best-Selling and Slow-Moving Products

POS system reporting allows you to identify which products are best-selling and which are slow-moving. This helps optimise stock allocation and prevents excess capital and warehouse space being tied up in slow-moving items.

-

Recommended practice: Analyse reports monthly to adjust inventory strategies and promotional activities.

-

Benefit: Improves capital efficiency and ensures popular products are always available.

5. Cross-Store Inventory Coordination

For retailers with multiple stores in Hong Kong, inventory coordination is crucial. Sales and stock needs vary by store; without unified management, some stores may run out while others have excess stock. Posify POS system centralises inventory data from all stores, providing real-time stock levels. Moreover, retailers can use the “Biz Manager App” on iPads or smartphones to perform stock checks and transfers, moving products from stores with surplus to those running low, ensuring popular items are always available. This improves product availability, enhances customer experience, and reduces inventory backlog and capital tie-up risks.

Conclusion: Make Full Use of POS Systems to Avoid Stockouts

By applying these five tips, Hong Kong retailers can significantly reduce stockout risks and improve operational efficiency. Posify’s cloud POS system provides comprehensive inventory management functions, including:

-

Integrated management across online and offline channels, multiple stores, and warehouses

-

Procurement, receiving, returns, and enquiries

-

Product serial number and batch tracking

-

Stocktaking and replenishment management

-

Inventory reporting and analysis

-

Supplier collaboration management

Explore Posify today to make your retail operations smarter, more efficient, and never worry about stockouts again!